Flexcon Helios

Energy Module in FlexSim for Smarter, Greener Operations

Energy Simulation

Simulate and refine your manufacturing facility’s energy use to lower costs, improve efficiency, and support smarter, more sustainable decision-making.

Why Energy Simulation Matters

Energy costs and sustainability goals are now critical considerations in manufacturing and logistics. Rising electricity prices, renewable energy intermittency, and carbon reduction commitments mean companies need accurate insights into when, where, and how energy is consumed. Traditional cost accounting only looks at total usage — but real savings and emissions reductions require understanding the timing and sources of energy use.

This is where FlexSim Helios comes in. Built to work seamlessly with your FlexSim models, Helios gives you a dynamic, visual, and data-rich view of energy use across your entire process — helping you make decisions that save money and reduce carbon impact without compromising productivity.

What is Flexcon Helios?

Developed by Flexcon s.r.l. in collaboration with FlexSim, Helios is an advanced energy simulation module that extends your existing process models to include:

- Accurate energy consumption mapping for every phase of your operations

- Indirect carbon emissions analysis based on real or simulated energy sources

- Cost calculations linked to energy usage and dynamic pricing

- Scenario comparison tools to test different operational strategies before

Key Capabilities

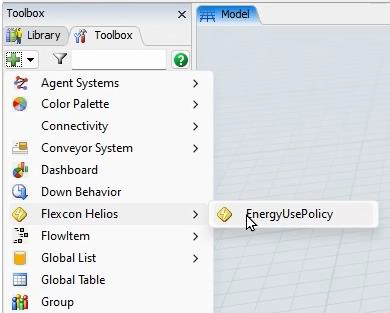

Energy Use Policies

Energy Use Policies

Dynamic Analysis & Visualization

Scenario Testing & Optimization

Applications

-

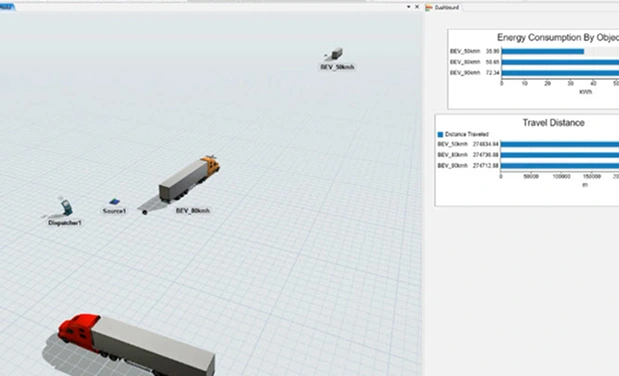

Predict When and Where Energy Is Used

Granular energy forecasting across production systems to optimize operations with precision. -

Simulate Time-Based Energy Use

Analyze and calculate energy consumption profiles (daily, weekly, or seasonal) for smarter planning around peak and off-peak rates. -

Optimize Production Schedules for Minimal Carbon Emissions and Costs

Simulate the impact of moving activities to different locations or times to reduce emissions and energy costs. -

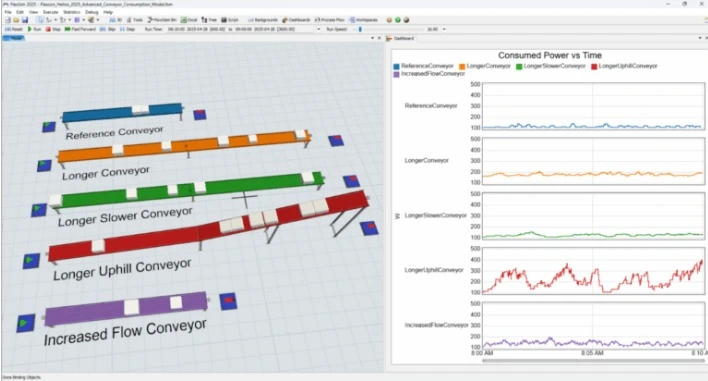

Model Conveyor Power Demand with Real Physics

Accurately simulate conveyor energy use using ISO 5048 formulas, considering factors like belt load, speed, slope, and resistances. -

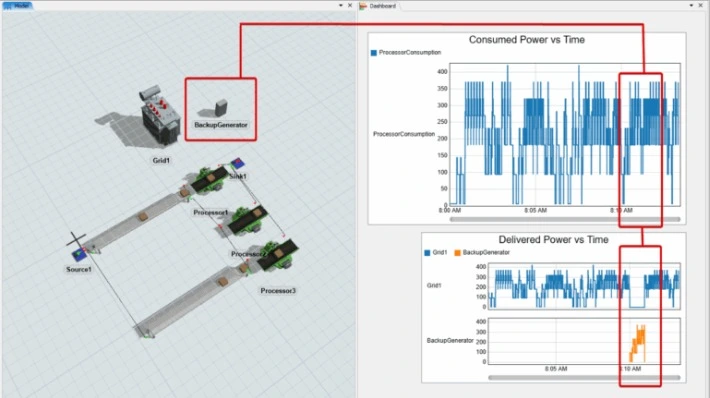

Handle Energy Source Failures with Resilience

Explore scenarios of energy source failures and simulate energy dispatch from backup systems for resiliency.

-

Link Energy Consumption to Equipment Speed

Explore scenarios of energy source failures and simulate energy dispatch from backup systems for resiliency.

How FlexSim Helios Works

Build Your Process Model

Start with a FlexSim simulation of your process, from manufacturing lines to distribution centers.Define Energy Use Policies

Set consumption rates for each piece of equipment or operational group based on its operating states.Configure Energy Sources

Assign each source its generation capacity, availability pattern, carbon intensity, and cost profile.Run & Analyze

Use dashboards to compare scenarios, measure KPIs, and visualize both operational and environmental impacts.

Business Benefits

Cost Reduction – Pinpoint inefficiencies and explore scheduling changes that lower energy bills.

Sustainability Impact – Quantify the carbon footprint of operations and explore renewable integration.

Better Infrastructure Planning – Size transformers, storage systems, and other components accurately.

Risk-Free Experimentation – Test operational strategies virtually before applying them in the real world.