Digital Twin Module

The Emulation Module in FlexSim takes your system modeling and simulation to the next level by enabling real-time control and integration with external systems. This advanced module allows you to mimic the actual control systems used in your operations, providing an accurate and interactive environment for testing, validation, and optimization.

Key Features

Real-Time Communication

The Emulation Module facilitates real-time data exchange between your FlexSim model and external control systems. This bidirectional communication ensures that your simulation mirrors real-world operations closely.

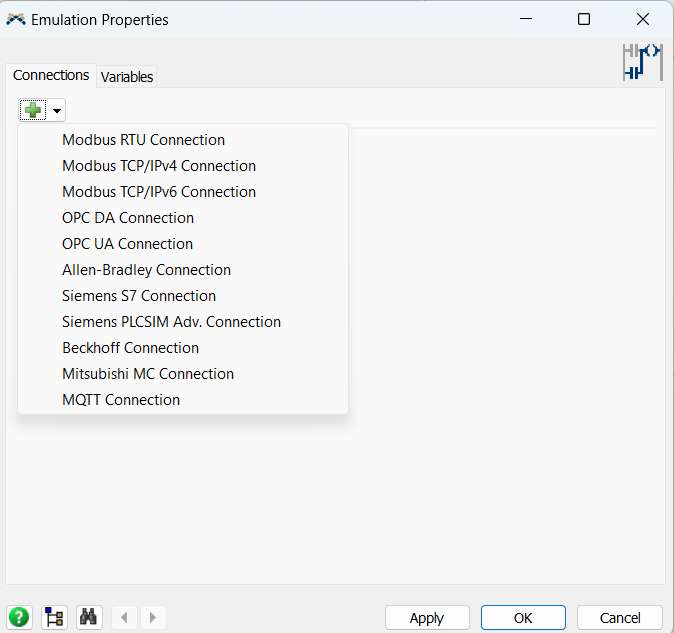

PLC and Control System Integration

Integrate your FlexSim model with Programmable Logic Controllers (PLCs) and other control systems to test and validate logic without interrupting actual production. This helps in identifying and resolving issues before implementing changes on the shop floor.

Advanced Testing Environment

Use the emulation capabilities to test new control strategies, verify system performance, and ensure seamless integration of new equipment. This reduces risk and enhances confidence in your control systems.

Interactive Debugging

Debug your control logic interactively within the FlexSim environment. Monitor and adjust control parameters in real-time, ensuring your system responds as expected under various scenarios.

Enhanced Decision Making

Gain deeper insights into how your control systems will perform in real-world conditions. Use this data to make informed decisions that improve efficiency, reduce downtime, and enhance overall system performance.

How It Works

With the Emulation Module in FlexSim, you can bridge the gap between simulation and real-world operations, ensuring your systems are robust, efficient, and ready for any challenge. Enhance your decision-making and optimize your control systems today with FlexSim’s powerful emulation capabilities.

Explore FlexSim’s Emulation Module and transform your system optimization approach.

Applications

Digital Twin is widely used across various industries for the below applications

Manufacturing

Optimizing production schedules, inventory levels, and resource allocation to improve efficiency and reduce costs.

Logistics and Supply Chain

Enhancing distribution strategies, vehicle routing, and warehouse operations.

Utilities and Infrastructure

Improving patient flow, resource utilization, and scheduling in hospitals and clinics

Benefits of Digital Twin

FlexSim toes the line between ease-of-use and capability. The main

benefits of using the digital twin module with FlexSim are as follows

Risk

Mitigation

Identify and address potential issues in control systems before implementation, reducing the risk of costly errors and downtime.

Cost

Savings

By simulating and validating changes in a virtual environment, you save on the costs associated with physical traits and errors.

Increased

Efficiency

Optimize control systems for better performance, leading to increased efficiency and productivity in your operations.